Discover the benefits of full device project management

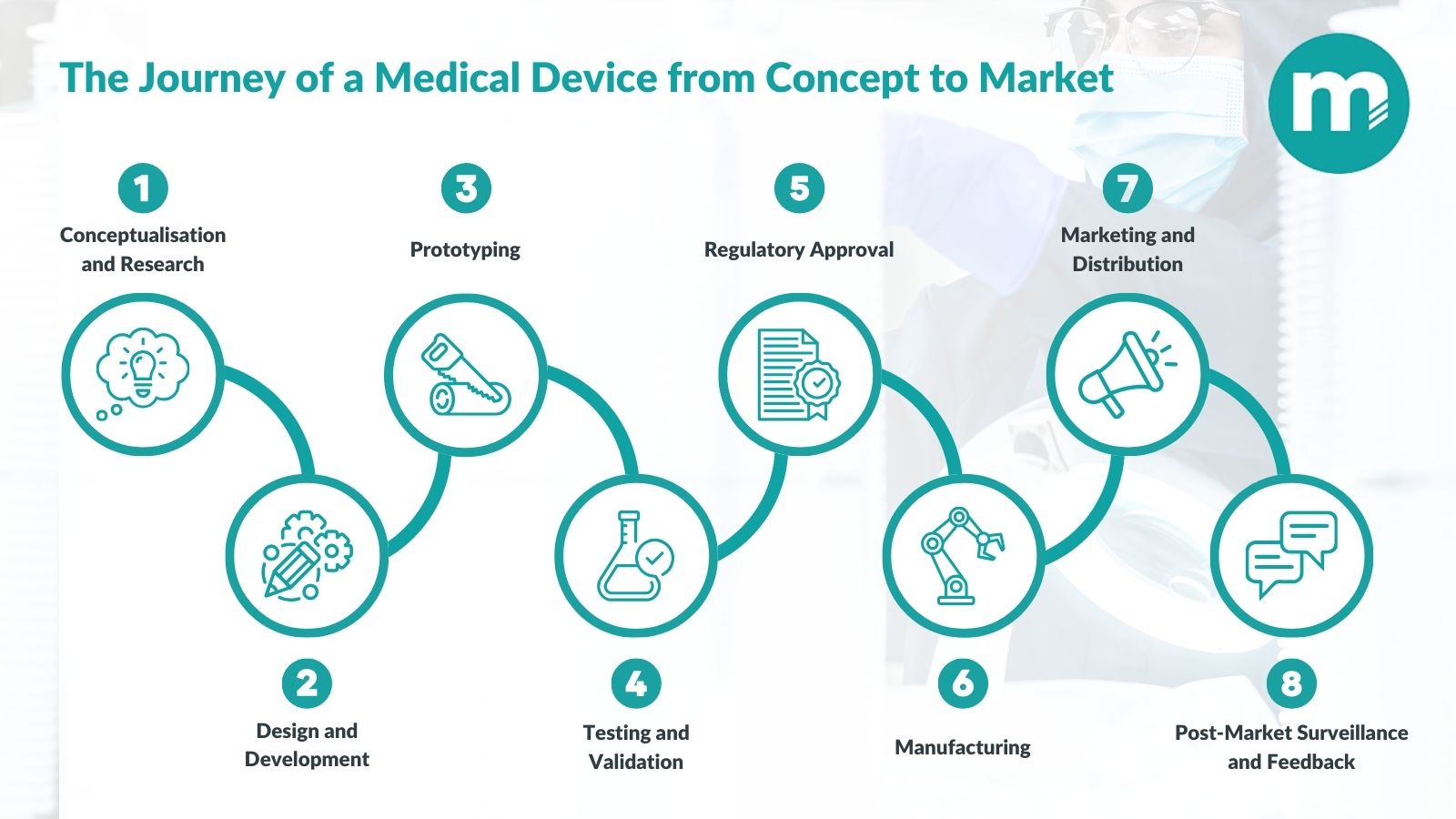

FULL MEDICAL DEVICE PROJECT MANAGEMENT

Look no further for a contract manufacturing partner who can fulfil all your medical supplies needs – from design for manufacturing through to medical product assembly, packaging, storage of medical equipment, components and raw materials and dispatch.

Whatever your medical manufacturing needs, Meridian Medical can help

Depending on what stage we become involved with your project, we will work closely with you to advise the best ways of progressing your ideas, designs or existing product(s) through our manufacturing processes – be this design, tooling, moulding, assembly, packaging, sterilisation, storage and dispatch, or all of the above.

Your products will be manufactured and assembled in our purpose-built manufacturing facilities, and every item tested and inspected to ensure only the highest quality products are released for use.

Meridian Medical’s full device project management services include: