It is critical that you get medical device labelling right. If your product is used improperly as a result of incorrect or insufficient labelling, you can be hit with significant fines, costly delays and reputational damage.

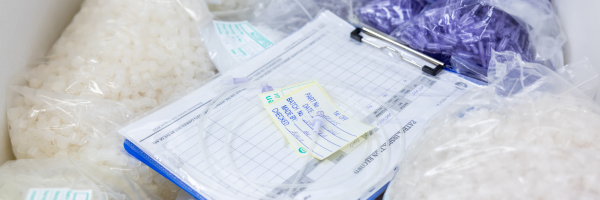

In medical device manufacturing, a medical device’s label must clearly display all the appropriate information as defined in BS EN ISO 15223-1:2016 and BS EN ISO20417 to ensure correct labelling, use and storage of the device.

How to get your medical device labelling right

To help you get medical device labelling right and avoid the risks associated with incorrect or insufficient labelling, here are six key points to consider when planning your medical product labelling:

- Prioritise labelling. Start thinking about labelling requirements at an early stage of designing a medical device, whilst reviewing the essential requirements checklist. This gives you invaluable time and flexibility to design your packaging correctly at the start of the project. Leave labelling management too late and addressing any issues could lead to costly delays.

- Quality labelling materials. The labels that you put on your medical products have to withstand storage, handling and distribution processes, not to mention actual use by patients and caregivers. As a result, labels should be durable, always remaining affixed to the device, and fully legible, either on the device itself or the medical device packaging.

- Market regulatory compliance. Medical device labelling requirements can vary according to the market and your labelling must adhere to the appropriate standards to secure market access. Requirements include a unique device identifier (UDI), product information, symbols as defined in ISO980 barcoding and safety information. In addition, language requirements must be complied with.

- Product labelling requirements. Medical devices can also require the inclusion of product-specific labelling or label content. For example, certain markets may require informational literature, information on performance testing and tolerances, and details of certain ingredients. In addition, medical devices that contain specific materials (such as plasticisers or latex) require specific label content and warnings.

- Labelling inspection process. You must ensure that a rigorous labelling inspection process is in place. This makes sure that label information is accurate before labels are applied to devices, checking that the UDI, date of expiration, batch or lot number and so forth, are correct. This labelling approval process should be well documented in a secure device record history.

- Labelling storage system. You must ensure that a comprehensive medical device labelling storage system is in place. This makes sure that labels are always properly identified and applied, safeguarding against the incorrect application of labels to products.

Medical device labelling and your product packaging partner

Medical device labelling can be challenging and getting it right can be a complex process. Expert help with labelling is one of the benefits of working with a contract manufacturer of medical devices.

The right medical device manufacturing partner will provide specialist advice on medical device labelling, guiding you through the process and requirements, and ensuring that you have the labelling that you need at the right time.

If your medical device contract manufacturer doesn’t offer these medical product labelling services, it’s time to reconsider your choice of partner.

Meridian Medical is an established and experienced contract medical equipment manufacturer, specialising in a wide range of medical device design, development and supply services.

To find out more about how Meridian Medical can help you with your medical product design and manufacture, get in touch today by filling out our online form or contacting us on 01903 732344 or info@meridian-medical.com.

Author: Andrew Wootten, Quality and Regulatory Manager

Andrew Wootten has been at the forefront of Meridian Medical’s quality and regulatory functions for over a decade. With a career in quality management that began in 1989 and extensive experience in the medical device sector since 2002, Andrew is a seasoned expert. He holds a City and Guilds certificate in Quality Assurance, a diploma in Quality Management from BSI, and is a certified internal auditor for ISO 13485, ISO 9001, and ISO 14001. Andrew ensures our regulatory compliance and drives the company’s commitment to excellence in quality and safety, making him a trusted authority in the industry. His deep understanding of global regulatory challenges and unwavering dedication to quality assurance position him as a key figure in delivering safe, compliant and top-quality medical devices.