The decision to use a contract manufacturer of medical devices can be a daunting one, as the success of this key relationship has important implications for the future success of your company.

Researching potential contractors thoroughly is therefore critical to the selection process. But what should you be looking for in a contract manufacturing partner?

Here’s a ten point guide as to what to look for in a contract manufacturer of medical disposables:

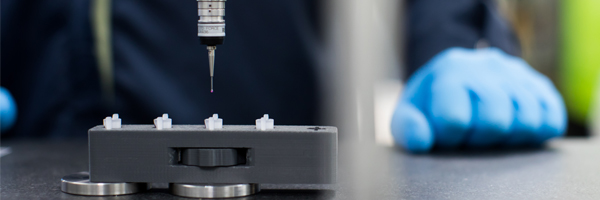

- Superb facilities which incorporate clean room injection moulding, as well as large clean room assembly and packing operations.

- An array of advanced equipment, such as our new Fanuc Roboshot a-S220IA, new material handling robot arm from Hi Tech Automation, the 6-axis M-10iA/8L robot conveyor system and our suite of all-electric Engel moulding machines.

- A full, end-to-end service offering, incorporating design for manufacturing, medical product assembly, packaging, storage of medical equipment, components and raw materials and dispatch.

- Experience and expertise, including a commitment to staff training and an excellent reputation in the marketplace.

- Evidence of longstanding relationships with valued customers.

- An emphasis on product quality, with systems and processes in place to ensure it. This means the design and production of medical supplies that meet the very highest standards in medical equipment safety, security, and reliability.

- Excellent customer service, delivered through great communication, providing knowledge, reliability and the utmost reassurance, with any problems dealt with promptly and always to customers’ satisfaction.

- An innovative and inventive approach – a contract manufacturing partner should be inventive and remain consistently up-to-date with the changing requirements of medical devices companies, embracing change and technological advances.

- Regulatory Compliance and Government Support – adherence to product safety standards and regulatory compliance is imperative throughout the whole operation. Ensure they have the correct and up-to-date certification, including ISO 9001, as well as the medical version of that ISO 3405, and are FDA approved.

- Cost effectiveness – a good contract manufacturer should offer the very best medical product design and manufacture at the most cost effective prices.

Meridian Medical is as an established and experienced contract medical equipment manufacturer, specialising in a wide range of sterile and non sterile medical device design, development and supply.

To find out more about how Meridian Medical can help you with your disposable medical product design or manufacture, get in touch today by filling out our online form, calling our sales team on 01903 732344 or emailing info@meridian-medical.com.

Author: James Fenton, Managing Director

James Fenton, Managing Director of Meridian Medical since 2017, has over 20 years of industry experience. He has been pivotal in developing and producing over 500 types of single-use medical devices, including CE-marked class 2 and 3 devices. With a strong focus on business strategy, project management and customer support, James ensures Meridian Medical's agility and innovation. His expertise is backed by qualifications in Business Studies and Medical Process and Equipment Validation, plus extensive industry training. James's insights into the industry that he has dedicated his entire career to provide a bank of invaluable information aimed at increasing knowledge of and driving advancements in medical device manufacturing.