A key area of medical device manufacturing is the development of new and improved medical products. Much of the development process can be outsourced to a contract medical device manufacturer but it is critical that you choose the right partner, one with the knowledge, expertise and services to achieve the results you want.

The following are the 12 key phases of medical device development. For the best results, your chosen outsourced manufacturing partner should be involved as early as possible in the development and design of a medical device.

A step-by-step guide to medical device development

Step 1: Idea creation (defining what your product does and what problem it solves, and why you are taking this step)

Step 2: Conduct market research (checking if your idea or a similar product already exists or is in development, and ascertaining if there is a market and sales volume potential)

Step 3: Competitor search and price-point checking (identifying competing manufacturers and products, and product price points, and potential competitive strategy)

Step 4: Design phase – this phase involves the following:

- Concept CAD modelling

- Initial design review

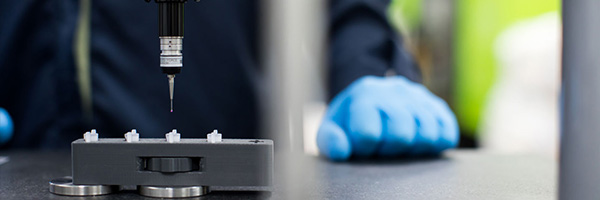

- Initial prototype creation (3D print to create one or two basic samples, probable use of incorrect material)

- Laboratory testing

- Second design review (design for manufacturability, material review, essential requirements feedback)

- Second prototype creation (prototype tooling, use of correct material and production to near spec standard)

- Field testing

- Final design review

- Obtain quote for production tooling and product manufacturing

Step 5: Secure CE mark and complete technical file

Step 6: Conduct laboratory work (bioburden, EtO residual, sterilisation, biocompatibility, shelf life and transit testing, etc.)

Step 7: Complete technical file (finalising the technical file when the product is finished, after completion of laboratory work)

Step 8: Secure regulatory approval (securing of regulatory approval from the chosen notified body)

Step 9: Issue initial production order (low volume for launch stock)

Step 10: Seek wider market feedback (gathering market intelligence post product certification and launch on customer approval, potential improvement, price point and market scope)

Step 11: Conduct product review (determining if the product needs new packaging or labels, should be made available in other sizes, would gain value if a kit of parts is added, etc.)

Step 12: Issue larger production order (based on market research and competitor volumes)

The benefits of working with a contract medical device manufacturer

Every phase of the medical device development process is important – each is critical to the quality, reliability and safety of your product, and to the reputation of your brand. For medical device companies that have a designed product to be manufactured but not the appropriate in-house facilities and resources, the best way to get this service and assurance is by working with a specialist contract medical device manufacturer.

The right contract medical device manufacturing partner will have specialist expertise and technology, including with regard to product development and prototyping. At the same time, they will have the quality system and assurance infrastructure, and the security, scalability and flexibility to meet your needs.

By offering an end-to-end contract manufacturing service, the right partner will be able to deliver the operational efficiency that translates into greater cost-efficiency for you.

The benefits of a full-service medical device manufacturing partner

When you select a specialist medical device manufacturing partner, it is vital that you choose one that offers full-service outsourcing. This combination of focus and scope is critical to the delivery of quality medical devices, market competitiveness and cost efficiency.

In addition to expertise and equipment considerations, a full-service contract medical device manufacturer will be able to offer important supply chain consolidation. The large resource pool that they offer is also important, as is their increased agility. These factors all translate into better service delivery and quicker time to market for your product.

With this level of service from your contract manufacturing partner, you are freed up to focus on core business activities, such as product marketing and new product development.

Meridian Medical is an established and experienced contract medical equipment manufacturer specialising in a wide range of medical device design, development and supply services.

To find out more about how Meridian Medical can help you with your medical product development and manufacture, get in touch today by filling out our online form or contacting us on 01903 732344 or info@meridian-medical.com.

Author: Paul Kearsley,

Technical Manager, Meridian Medical

Paul Kearsley brings a lifetime of engineering expertise to his role as Technical Manager at Meridian Medical. With an HNC in Mechanical Engineering and a foundation built during a four-year engineering apprenticeship, Paul has spent over 40 years running his own design company. Over the decades, he has designed more than 1,000 consumer, industrial, and medical devices, showcasing his ability to deliver innovative solutions across a broad spectrum of industries.

A pioneer in the transition from traditional drafting techniques to modern CAD workflows, Paul began his career on the drawing board, adopted AutoCAD 2D early on, and embraced 3D modelling with SolidWorks in 1997. His vast experience and technical leadership play a key role in Meridian Medical’s commitment to producing high-quality, single-use medical devices.