Meridian Medical has been producing line sets (infusion lines, anaesthetic line sets, drug delivery and solution sets) for over 30 years and, having built a solid expertise in the design and manufacture of these types of medical devices, we have created a detailed guide of some of the key aspects that should be considered throughout the whole manufacturing process.

This new guide has been produced to assist those involved in the manufacture or procurement of outsourced manufacturing services for these types of medical devices. In this article we give you a taste of the more detailed information the guide contains, including an overview of the points to be considered when manufacturing line sets.

Line set manufacturing preparation phase

Having selected a line set solution, your first consideration should be the general Safety and Performance Requirements (SPRs), previously known as the Essential Requirements Checklist.

This will enable you to build any performance, safety and test requirements into your specification at the front end and save time on any redesigns requested by regulatory authorities further down the line. It should also help you answer questions such as:

- What is the purpose of the device?

- How will it be sterilised?

- How will the device be used?

- What connections does the device require?

Once you have completed the SPRs, you should have a good idea of specification of the required device.

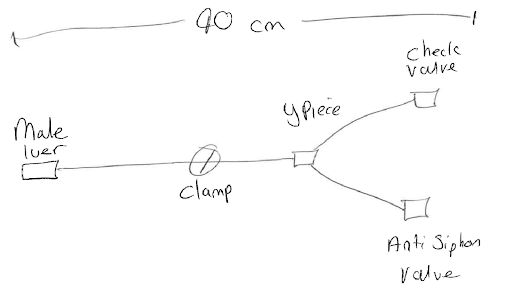

At this stage, create a quick pen drawing of the set with notes. Include any lengths, connection types, filters, check valves and so on. Here’s an example below:

Image 1: sample line set draft

Line set device specification

Once you have a rough idea of what you’re trying to manufacture, it’s important to look at each of the parts of the line set in more detail. Consider the requirements for the following:

- Tube size

- Tube material

- Tube lengths

- Clamps

- Valves and luer fittings, also known as check valves

- Connecting your tubes and fittings

- The sterility and length of use (single use or reusable)

- Bonding of the parts together

Further detailed guidance is available in our line sets guide. Once all the parts, sizes, materials and the method of sterilisation have been considered, the sample drawing should be updated.

Medical line set testing and inspection

The tests involved in ensuring your line set design meets the requirements for intended use will be highlighted in your completed SPRs. Product testing could well include many of the following (depending on your application):

- Flow rate testing

- Destructive force testing of fittings

- Leak testing

- Blocked tube testing

- Valve crack pressure testing

- Shelf-life testing

- Sterility testing

- Bioburden testing

- ETO residual testing

Some of these tests will be conducted before the device is given approval for manufacture, or during the production phase. They will be carried out either on all devices or as a sample inspection.

Medical line set packaging

Your manufacturer may have several packaging options and suggestions for your line set, which will be based on the volume of production, shelf life, number of devices per box and method of sterilisation.

At Meridian Medical we will always opt for peel pouches, as they are cost effective, can be printed or labelled, have a good shelf life, pack flat and have a clear side to show the device (this is useful for Quality Assurance).

Medical line set costing

There are many aspects that could affect the cost of your line set. The fewer parts you use and the faster the device is to produce, the cheaper it will become. Your device may also be simple but have an unnecessarily complicated testing and inspection procedure that will increase production time.

If you have a price point to meet, share this with your manufacturer and they can suggest ways to reduce cost if required.

Talk to the experts

It’s important to remember that each application is unique and will therefore be likely to have its own specific challenges and requirements, as such, it’s important you discuss these with a specialist medical contract manufacturing partner with the experience to correctly assess your device specification and the expertise to carry out the production to the highest standard.

Meridian Medical is an established and experienced contract medical equipment manufacturer specialising in a wide range of medical device design, development and supply services. We have over 30 years’ experience working with a number of the UK’s leading medical device companies and produce over 5 million line sets per year.

To find out more about how Meridian Medical can help you with your medical product design and manufacture, get in touch today by filling out our online form or contacting us on 01903 732344 or info@meridian-medical.com.

Author: James Fenton, Managing Director

James Fenton, Managing Director of Meridian Medical since 2017, has over 20 years of industry experience. He has been pivotal in developing and producing over 500 types of single-use medical devices, including CE-marked class 2 and 3 devices. With a strong focus on business strategy, project management and customer support, James ensures Meridian Medical's agility and innovation. His expertise is backed by qualifications in Business Studies and Medical Process and Equipment Validation, plus extensive industry training. James's insights into the industry that he has dedicated his entire career to provide a bank of invaluable information aimed at increasing knowledge of and driving advancements in medical device manufacturing.