Medical device manufacturing is a complex and highly regulated industry that requires a great deal of attention to detail. One of the key principles that manufacturers should keep in mind is that less is more when it comes to designing, manufacturing, and packaging medical devices.

In this blog post, we explore the reasons why less is more in medical device manufacturing.

- Simplicity enhances safety

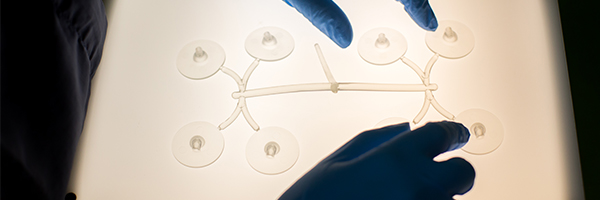

Medical devices are designed to be used in high-stress, high-stakes situations. Therefore, the simpler the design of the device, the less room there is for error. When a device has fewer parts, there are fewer opportunities for malfunctions or defects to occur. Additionally, simple designs are easier to maintain and service, which helps to ensure that the device is always functioning to the intended design specification.

- Lower cost of production

When it comes to medical manufacturing, less is more in terms of production costs. The fewer components a device has, the less time it takes to manufacture, assemble, and package. Additionally, simpler designs require fewer raw materials, which reduces material costs. This translates to a lower cost of production, which can make medical devices more affordable for healthcare providers and patients.

- Improved quality control

In medical manufacturing, quality control is of utmost importance. Simpler designs make it easier to implement and maintain a quality control system. The more complex a device is, the more difficult it becomes to ensure that each part meets the necessary specifications. By keeping designs simple, manufacturers can more easily identify and correct any quality control issues that arise.

- Increased accessibility

Finally, simpler designs can make medical devices more accessible to a wider range of users. This is especially important in developing countries, where access to medical devices can be limited. When devices are easier to manufacture and more affordable, they can be made available to more people who need them.

In conclusion, less is more in medical manufacturing. By keeping designs simple, manufacturers can enhance safety, lower the cost of production, improve quality control, and increase accessibility. By prioritising simplicity in medical device design and manufacturing, manufacturers can create products that are more effective and efficient, and ultimately benefit patients and healthcare providers.

Meridian Medical is an established and experienced contract medical device manufacturer specialising in a wide range of medical devices. We offer design, regulatory assistance, cleanroom injection moulding, cleanroom assembly, contact packaging and sterilisation Management. We have over 30 years’ experience supplying UK and European companies.

To find out more about how Meridian Medical can help you with your medical device manufacture, get in touch today by filling out our online form or contacting us on 01903 732344 or info@meridian-medical.com.

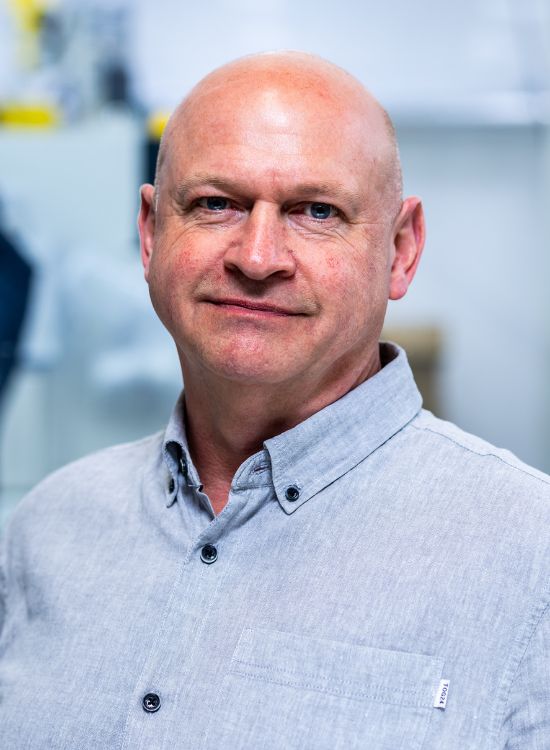

Author: Paul Kearsley,

Technical Manager, Meridian Medical

Paul Kearsley brings a lifetime of engineering expertise to his role as Technical Manager at Meridian Medical. With an HNC in Mechanical Engineering and a foundation built during a four-year engineering apprenticeship, Paul has spent over 40 years running his own design company. Over the decades, he has designed more than 1,000 consumer, industrial, and medical devices, showcasing his ability to deliver innovative solutions across a broad spectrum of industries.

A pioneer in the transition from traditional drafting techniques to modern CAD workflows, Paul began his career on the drawing board, adopted AutoCAD 2D early on, and embraced 3D modelling with SolidWorks in 1997. His vast experience and technical leadership play a key role in Meridian Medical’s commitment to producing high-quality, single-use medical devices.