At Meridian Medical, we believe exceptional product performance and patient safety go hand in hand. That’s why our Medical Device Testing service is designed to be comprehensive, transparent, and tailored to your device’s unique needs – from concept validation through final qualification.

As a leading medical device manufacturer, we combine technical precision with regulatory insight to ensure every device meets performance, usability, and safety standards before it reaches the market.

Why Meridian Medical Testing Stands Out

From Early Design to Final Validation

Our medical device verification testing and validation support begins as early as the design stage, helping to identify and mitigate risks before they escalate. Whether you’re refining specifications or optimising manufacturability, our experts adapt seamlessly to your development milestones – ensuring compliance with key medical device testing requirements.

A Suite of Specialised Testing Services

We provide a full range of medical device testing services backed by advanced methodology and accredited facilities. Our core capabilities include:

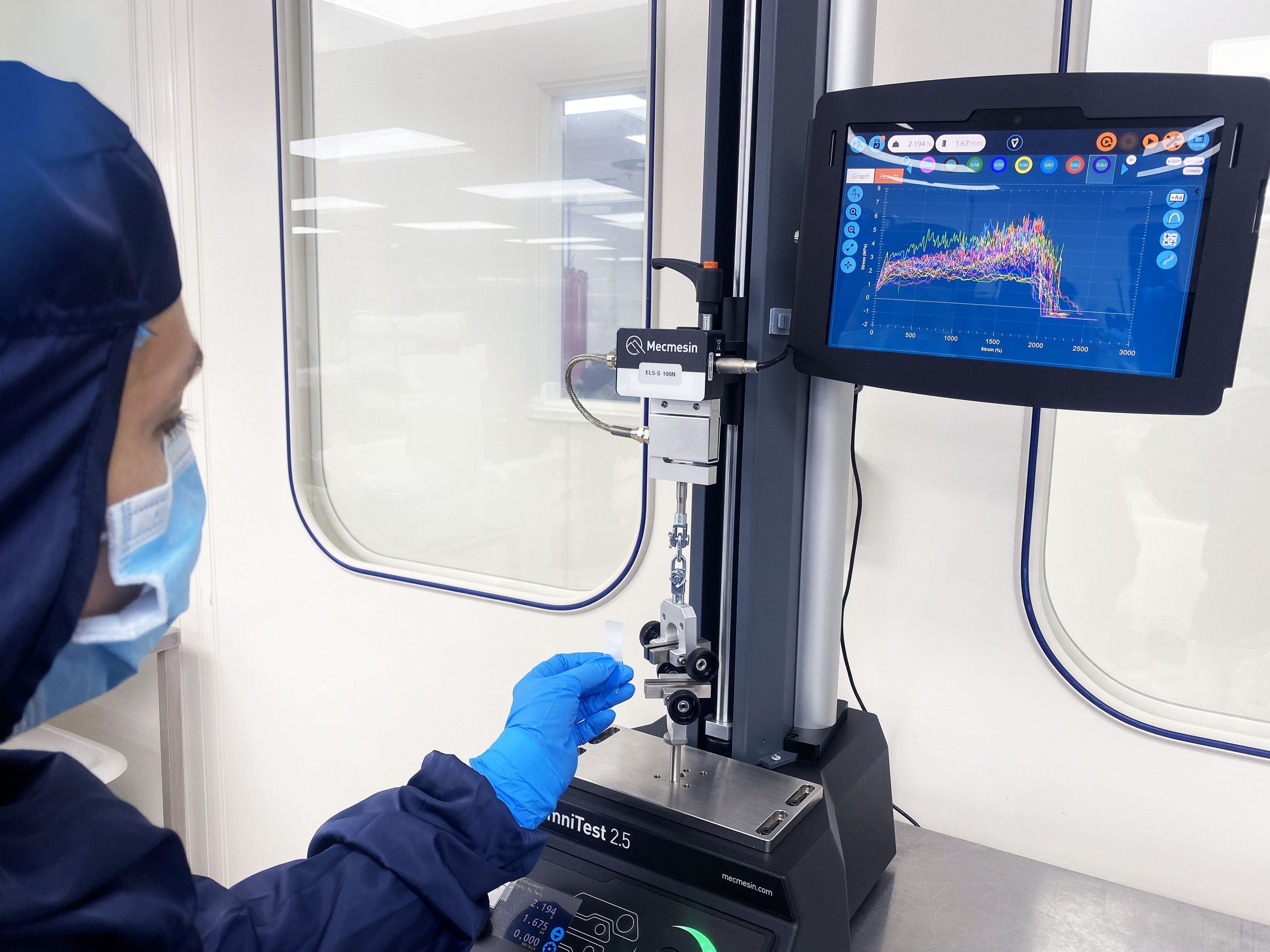

- Functional & Mechanical Integrity: Pull, force, dimensional, and in-process gauging testing to ensure consistent medical device performance testing and reliability.

- Leak & Block Testing: Using Furness fixture technology, we detect leaks, blockages or assembly defects that could compromise function or safety – key medical device safety testing.

- Sterility Assurance & Microbiology Testing: Working with our laboratory partners, we perform medical device microbiology testing to measure colony-forming units (CFUs) and ensure minimal microbial contamination – critical for sterilisation success and patient safety.

- Shelf-Life Evaluation: Conducted per BS EN ISO 11607-1:2020, combining real-time and accelerated ageing to predict long-term packaging and device stability. Our product and package integrity testing ensure barrier performance and sterility maintenance are sufficient for the defined lifetime of the device.

- Residuals & Contaminant Testing: Our lab partners can provide bioburden, endo toxin and fungal counts to ensure that your process is clean and free from gram negative bacteria and toxins, as well as Ethylene oxide residual and sterility testing for process verification.

Cleanroom-Certified Testing Environments

All critical testing takes place in controlled cleanrooms featuring HEPA filtration, positive pressure management and strict microbiological monitoring. This ensures the precision and reliability required for regulated medical device testing labs.

How Our Testing Benefits You

Risk Reduction, Early in Development

By embedding medical device product testing early into the earliest design phases, we help you prevent failures, delays or costly recalls.

Customised Testing Roadmaps

Every device is unique. Our experts create tailored plans for medical device compatibility testing, medical device usability testing and packaging validation – so you only invest in what’s essential.

Efficient, Data-Driven Insights

Our combination of real-time and accelerated ageing studies, combined with bioburden and residual data, enables evidence-based decisions on shelf life and product safety.

Regulatory Confidence & Streamlined Approvals

With ISO-certified medical device testing methods and documentation, your design control evidence and technical files are audit-ready and streamlined for faster market access.

Ready to Talk About Your Device?

Let’s co-create a testing strategy that supports your device’s safety, performance, and market success. Whether you’re validating a new design or enhancing an existing product, Meridian Medical’s medical device testing services deliver clarity, confidence and regulatory readiness.

Get in touch today to discuss your medical device testing or packaging testing project. Our specialists will work with you to build a validation roadmap that meets your objectives and ensures compliance at every stage.